HOME > Business > Logistics Automation

OOKSAN IMT Co., Ltd. is your partner that

provides the total solution of production equipment with the

use of customer-optimized technology and service.

To respond to users’ diverse needs, OOKSAN IMT Co., Ltd.

provides the high-speedy and precise optimal systems for Proposal,

Engineering, Making & Installation, and Follow-up Management in line with global trends.

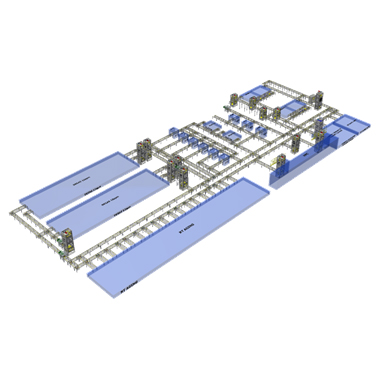

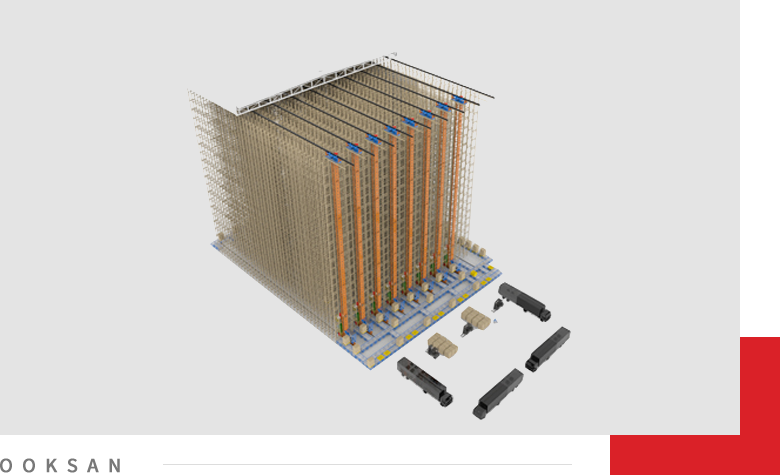

The standardized design of OOKSAN Co., Ltd. Automated Storage/Retrieval System makes it possible to respond actively to system expansion and remodeling, and supports solutions that meet various conditions, such as high load, high rise, and high speed. In addition, it achieves a lot of industrial performance in diverse areas, including electricity & electronics, automobile, food products, and pharmaceuticals.

Engine & Trans mission AS/RS (HYUNDAI WIA)

Engine & Trans mission AS/RS (HYUNDAI WIA)  Engine Warehouse (HYUNDAI WIA)

Engine Warehouse (HYUNDAI WIA)  Engine Warehouse (HYUNDAI WIA)

Engine Warehouse (HYUNDAI WIA)  Engine Warehouse (HYUNDAI WIA)

Engine Warehouse (HYUNDAI WIA)  Finished Product & Heat Treatment Warehouse Beijing Dymos

Finished Product & Heat Treatment Warehouse Beijing Dymos  Painted body shop AS/RS(Kia motors Georgia U.S.A.)

Painted body shop AS/RS(Kia motors Georgia U.S.A.)  Nongshim Yanbian Baeksansu

Nongshim Yanbian Baeksansu  Nongshim Yanbian Baeksansu

Nongshim Yanbian Baeksansu

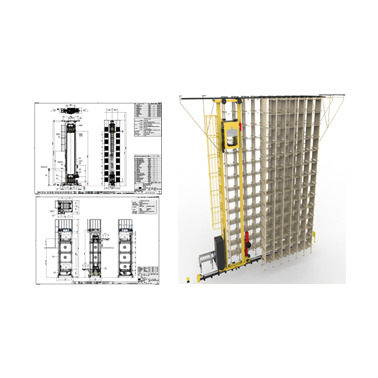

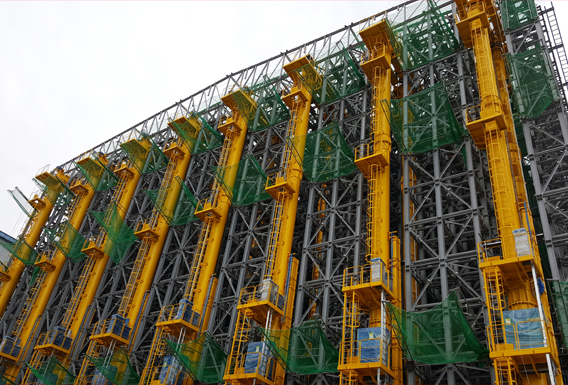

Hyundai Steel Sucheon Factory High-rise Warehouse HBS Stacker Crane & Rack

Hyundai Steel Sucheon Factory High-rise Warehouse HBS Stacker Crane & Rack | Year | Achievements |

|---|---|

| 2020 | POSCO Chemical, Unburned Refractory Factory Auto Warehouse System |

| 2018 | Namsung Precision, Piping Parts Automated Warehouse |

| 2017 | Hyundai Motor Company, Ulsan Factory Integrated Engine Auto Warehouse Renault Samsung Motors, CYLINDER BLOCK Automated Warehouse Kia, A/P CYLINDER HEAD Automated Warehouse Nongshim, Yanbian Baeksansu Mineral Water Auto Warehouse 2nd |

| 2016 | Hyundai Steel, Suncheon Factory High-rise Warehouse (HBS) S/Crane Manufacturing (17ton load) Kia, Adaptor Warehouse |

| 2015 | Nongshim, Yanbian Baeksansu Mineral Water Auto Warehouse 1st |

| 2014 | Nexen Tire, Changnyeog 2nd Auto Warehouse |

| 2013 | Hyundai Wia, Engine & Transmission Auto Warehouse |

| 2012 | LG Chem, EVA Auto Warehouse Celltrion, Drug Storage Warehouse IPC Saudi Arabia, IPC EVA Warehouse S/C (Saudi Arabia) Hanwha Solutions, EVA Auto Warehouse S/C Nexen Tire, Qingdao Factory Auto Warehouse |

| 2011 | Hyundai Hysco, Coil handling system S/C (15ton load) Nexen Tire, Changnyeong 1st Auto Warehouse Johnson Controls, Car Seat Assembly AS/RS |

| 2010 | Hyundai Motor Company, Transmission Auto Warehouse AFT Korea Wiring Warehouse (Beijing Hyundai Motor Company) |

| 2009 | Johnson Controls, Car Seat Assembly AS/RS |

| 2008 | Donghee Industries Co., Ltd., Coating Line Auto Warehouse (State of Georgia, USA) Hyundai Rotem, Wiring Feeding Line SEIL, Cold storage Stacker Crane |

| 2007 | Harim, Cold-Storage Warehouse S/C |

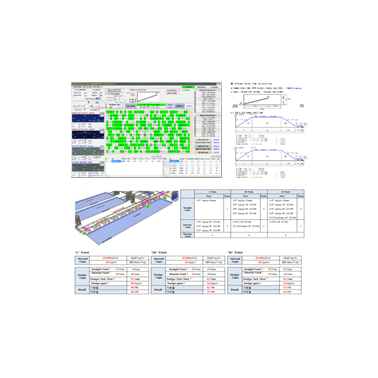

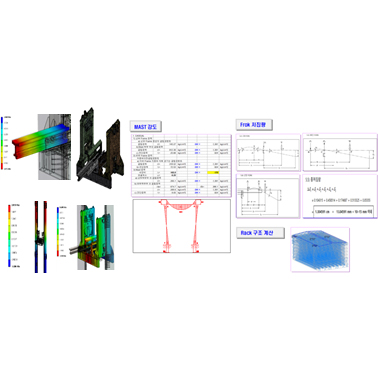

01Consulting

02Design

03Manufacturing/Installation

04Test-operation / After-sales service