HOME > Business > Logistics Automation

OOKSAN IMT Co., Ltd. is your partner that

provides the total solution of production equipment with the

use of customer-optimized technology and service.

To respond to users’ diverse needs, OOKSAN IMT Co., Ltd.

provides the high-speedy and precise optimal systems for Proposal,

Engineering, Making & Installation, and Follow-up Management in line with global trends.

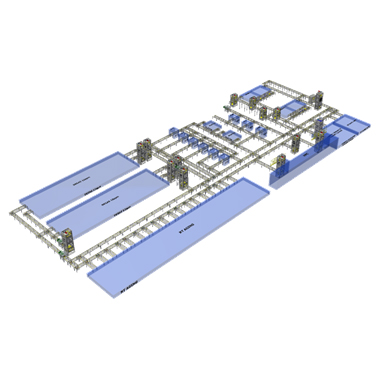

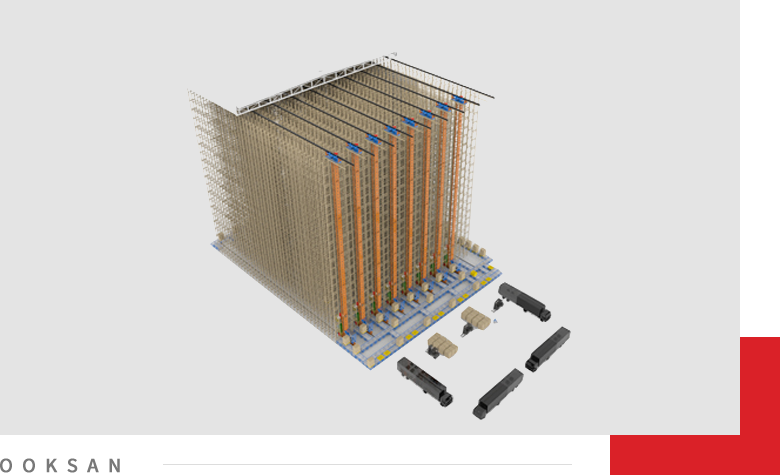

The standardized design of OOKSAN Co., Ltd. Automated Storage/Retrieval System makes it possible to respond actively to system expansion and remodeling, and supports solutions that meet various conditions, such as high load, high rise, and high speed. In addition, it achieves a lot of industrial performance in diverse areas, including electricity & electronics, automobile, food products, and pharmaceuticals.

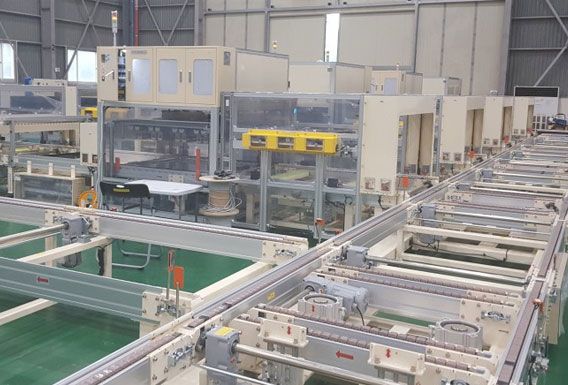

Guolian, China Pouch Aging Line Conveyor System

Guolian, China Pouch Aging Line Conveyor System  Guolian, China Pouch Aging Line Conveyor System

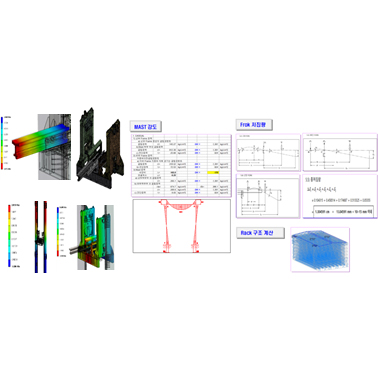

Guolian, China Pouch Aging Line Conveyor System  Guolian, China Pouch Aging LineRack

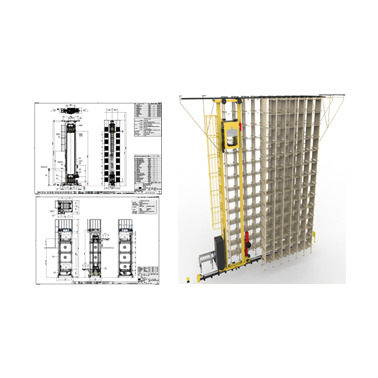

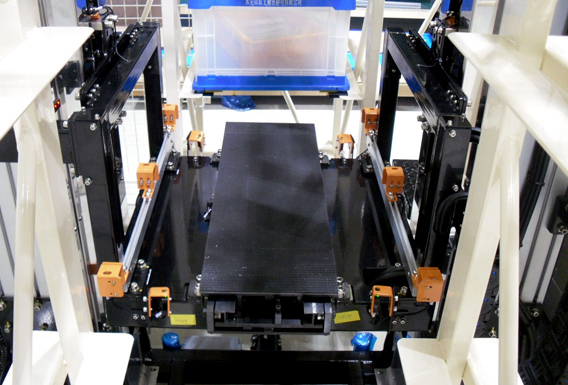

Guolian, China Pouch Aging LineRack  Guolian, China Pouch Aging Line Stacker & Rack

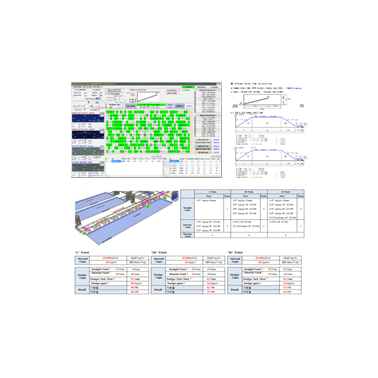

Guolian, China Pouch Aging Line Stacker & Rack  Samsung SDI Prismatic Aging Line Shop Test

Samsung SDI Prismatic Aging Line Shop Test  Samsung SDI Prismatic Aging Line Shop Test

Samsung SDI Prismatic Aging Line Shop Test  PNE Tianneng Pouch Charging/Discharging Warehouse

PNE Tianneng Pouch Charging/Discharging Warehouse  Mobile Module Stock AS/RS (1,000 ~ 10,000class Clean Equipment) SAMSUNG DISPLAY Dongguan China

Mobile Module Stock AS/RS (1,000 ~ 10,000class Clean Equipment) SAMSUNG DISPLAY Dongguan China  Mobile Module Stock AS/RS (1,000 ~ 10,000class Clean Equipment) SAMSUNG DISPLAY Dongguan China

Mobile Module Stock AS/RS (1,000 ~ 10,000class Clean Equipment) SAMSUNG DISPLAY Dongguan China | Year | Achievements |

|---|---|

| 2021 | Samsung SDI Hungray Car battery Stack Aging Line / Module & Pack cell AS/RS |

| 2020 | Samsung SDI Hungary Car battery Aging Line / Module & Pack cell AS/RS |

| 2019 | Jinping New Energy Cylindrical 32700 Cell Automated Aging Line |

| 2018 | Samsung SDI Car bettery Aging Module Line Samsung SDI Hungary Car bettery Aging Line 4 PNE Guolian Pouch Formation Process Logistics Automation Equipment Samsung SDI Mid-Large Cheonan M Line AG Automation Equipment |

| 2017 | PNE Huizhou EVE Formation Process Logistics Automation Equipment |

| 2016 | PNE Tianneng Pouch Charging/Discharging Warehouse |

| 2014 | Samsung SDI, Automotive Battery Cell China Line 1 Samsung SDI, Automotive Battery Cell Formation Line 4 |

| 2013 | Samsung SDI, Automotive Battery Cell Formation Line 3 Samsung Display, Mobile Module Auto Warehouse (10,000 Class clean room) |

| 2012 | Samsung SDI, Automotive Battery Cell Formation Line 1 |

| 2010 | Samsung SDI, Charging/Discharging Auto Warehouse Remodeling |

| 2008 | Samsung SDI, Formation #1 S/CRANE Making |

01Consulting

02Design

03Manufacturing/Installation

04Test-operation / After-sales service